Understanding Electromagnetic Shielding Materials

Electromagnetic interference (EMI) has become a pressing issue in our digitally driven world, where electronic devices and wireless communication are pervasive. Consequently, the importance of effective electromagnetic shielding materials cannot be overstated. These materials serve as barriers, protecting sensitive electronic systems from unwanted external electromagnetic fields, facilitating smoother, more reliable device operation across various applications.

What is Electromagnetic Shielding?

Electromagnetic shielding is the process of containing or reducing electromagnetic fields in a given area by means of various materials or enclosures. This act of shielding is critical for ensuring that electronic devices function as intended without interference, which can lead to data loss, device malfunction, and even safety hazards.

The Science Behind Shielding

The science of electromagnetic shielding is fundamentally rooted in electromagnetic theory. Shielding effectiveness depends on the material’s conductivity, thickness, and permeability. When electromagnetic waves encounter a shielding material, their energy is either reflected, absorbed, or transmitted. The goal is to maximize reflection and absorption while minimizing transmission.

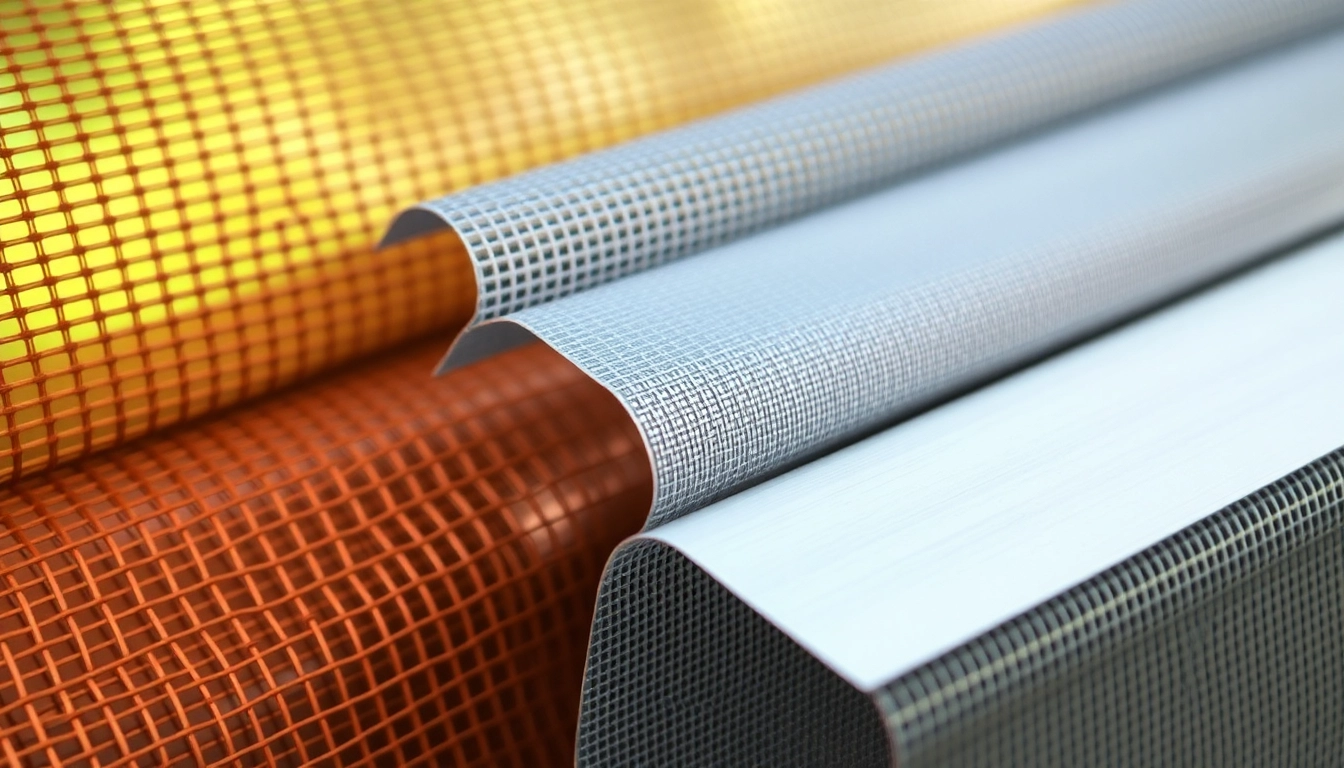

Common materials used in shielding include conductive metals, such as copper and aluminum, which are typically used due to their high electrical conductivity. Their ability to reflect and absorb electromagnetic radiation makes them ideal choices for creating effective barriers.

Importance in 21st Century Technology

As technology continues to advance, the prevalence of electronic devices increases exponentially—leading to more devices operating simultaneously in close proximity. This situation heightens the potential for EMI, which can disrupt communications in medical equipment, consumer electronics, and even telecommunications infrastructure. Therefore, the development and implementation of effective electromagnetic shielding materials are crucial for maintaining performance integrity and compliance with regulatory standards.

Common Types of Electromagnetic Shielding Materials

Metals Used for Shielding

Metals form the backbone of most electromagnetic shielding solutions. The common metals used include:

- Copper: Known for its excellent electrical conductivity, copper provides high attenuation rates for both electrical and magnetic fields.

- Aluminum: Lighter and less expensive than copper, aluminum is often utilized in applications where weight is a concern without significantly sacrificing performance.

- Steel: Often used for structural shielding, steel’s high density provides good overall protection but may require treatment to enhance conductivity.

- Nickel: Typically alloyed with copper or used as a coating, nickel improves corrosion resistance and assists with shielding effectiveness.

Ceramic and Polymer Shielding Solutions

Alongside metals, ceramics and polymers have emerged as promising materials for EMI shielding. These materials can provide lightweight and flexible shielding options. Conductive polymers, such as polyaniline or polypyrrole, are examples of flexible materials that are increasingly being researched for use in modern electronic applications.

Ceramics, while traditionally not as conductive, can provide effective shielding when combined with metal elements. They are particularly valuable in high-temperature applications.

Nano-composites in Electromagnetic Shielding

With advancements in materials science, the development of nano-composites offers exciting possibilities for electromagnetic shielding. Composites that integrate nanoparticles with more traditional materials can create advanced shielding solutions that capitalize on the unique properties of various materials at the nano-level. These composites can improve electrical and magnetic shielding effectiveness while also reducing weight and improving flexibility.

For example, carbon-based nano-materials like graphene and carbon nanotubes have gained attention for their potential in creating ultra-lightweight yet highly effective shielding materials. Research is ongoing to optimize their benefits in practical applications.

Comparing Effectiveness: Metal vs. Non-metal Shielding

Pros and Cons of Metal Shielding

Metal shielding is often favored due to its traditional effectiveness and availability. However, it does come with its pros and cons:

- Pros: High conductivity, excellent reflection and absorption of electromagnetic fields, and well-understood manufacturing processes.

- Cons: Weight and rigidity may pose challenges in applications requiring flexibility and lightweight materials.

When to Use Non-metal Shielding?

In scenarios where weight, flexibility, or corrosion resistance is paramount, non-metal shielding solutions may be more appropriate. For instance, consumer electronics frequently integrate polymer-based shielding to create lighter and more versatile designs. Non-metal options are also becoming crucial in wearable technology, where comfort and flexibility are key factors.

Case Studies of Effective Shield Designs

To better understand the application of these materials, examining real-world scenarios can illustrate their effectiveness. For example, in the medical field, MRI machines utilize advanced copper and aluminum shielding to prevent interference from external signals and enhance imaging accuracy. Similarly, automotive manufacturers are increasingly embedding EMI shielding in their electronic control units to ensure vehicle systems operate flawlessly amid numerous competing signals on the road.

Applications of Electromagnetic Shielding Materials

Electronics and Consumer Devices

In the realm of electronics, shielding materials are used pervasively across devices like smartphones, laptops, and tablets. Effective electromagnetic shielding in consumer technology ensures that devices maintain functionality amidst the high levels of wireless communication and data processing that occur simultaneously.

Medical Equipment Requirements

Medical equipment, particularly devices like MRI machines and surgical instruments, require stringent shielding to avoid interference that could compromise patient safety or the accuracy of the readings. Effective shielding in this domain should mitigate not only EMI but also RF interference, thereby ensuring that sensitive operations proceed without complications.

Automotive and Aerospace Uses

With the rapid evolution of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), automotive applications of electromagnetic shielding materials are expanding. EMIs in vehicles can cause malfunctions or degrade performance; thus, manufacturers are incorporating various shielding materials to maintain reliable operations. Additionally, in aerospace, shielding is critical due to the intense electromagnetic environments that aircraft experience during flight. Shielding ensures that vital avionics systems are protected against potential disruptions.

Choosing the Right Electromagnetic Shielding Material

Factors to Consider and Evaluate

When seeking the optimal electromagnetic shielding material, various considerations must be addressed:

- Material Conductivity: Higher conductivity often correlates with better shielding efficacy.

- Weight Requirements: Assess whether the application demands lightweight materials, especially in aerospace or wearable technology.

- Environmental Considerations: The material must withstand potential exposure to humidity, temperature fluctuations, and corrosive elements in its intended environment.

- Cost-effectiveness: Budget constraints also play a significant role in material selection. Evaluating longevity versus initial cost can lead to informed decisions.

Best Practices for Implementation

Implementing effective shielding requires a strategic approach:

- Perform EMI analysis: Understanding the specific electromagnetic environment helps determine the appropriate shielding solution.

- Integrate shielding into the design: Early incorporation into product design maximizes space and effectiveness.

- Regular Testing: Conduct ongoing testing to ensure shielding remains effective over time, adjusting designs as necessary.

Future Trends in Shielding Material Technology

The future of electromagnetic shielding materials is poised for innovation. Trends to watch include:

- Smart shielding: Materials that can adapt to different frequencies and environments, potentially integrating sensing technologies for improved effectiveness.

- Biocompatibility: As industries like medical technology advance, research in biocompatible shielding materials will become vital.

- Eco-friendly options: With increasing emphasis on sustainability, eco-friendly materials that provide effective shielding without contributing to environmental harm will gain traction.