Introduction to Injection Molding Machines

In the realm of industrial manufacturing, efficiency, accuracy, and scalability are paramount. One of the pivotal technologies that embodies these attributes is the Injection Molding Machine. These machines revolutionize the production process by allowing manufacturers to create complex plastic parts with speed and precision. In this comprehensive guide, we will explore various aspects of injection molding machines, their benefits, types, and detailed insights into the prominent series offered by TopStar — a leader in the field.

What is Injection Molding?

Injection molding is a manufacturing process that involves the injection of molten material (typically thermoplastics) into a mold to produce intricate, detailed parts. This technique allows for the mass production of parts that are uniform in quality and dimension. The process commences with the melting of raw material in a heated chamber, after which it is injected into a pre-designed mold using high pressure. Once the material cools and solidifies, the mold is opened, and the finished component is ejected. This method is prevalent in various industries, including automotive, consumer goods, electronics, and healthcare, due to its speed, efficiency, and the ability to produce complex geometries.

Benefits of Using Injection Molding Machines

The advantages of injection molding are vast and play a crucial role in its widespread use across numerous sectors. Here are some of the primary benefits:

- High Efficiency: Injection molding is designed for rapid production cycles, enabling manufacturers to produce thousands of parts per hour.

- Consistent Quality: The automated nature of the process ensures uniformity in production, with minimal variance from one part to another.

- Complex Designs: The ability to create intricate shapes and structures that may be difficult or impossible to achieve with other manufacturing methods is one of injection molding’s key strengths.

- Material Versatility: A wide range of thermoplastics and thermosets can be used, allowing for flexibility in production.

- Minimal Waste: The process is highly efficient in material usage, with excess material easily recycled in many cases.

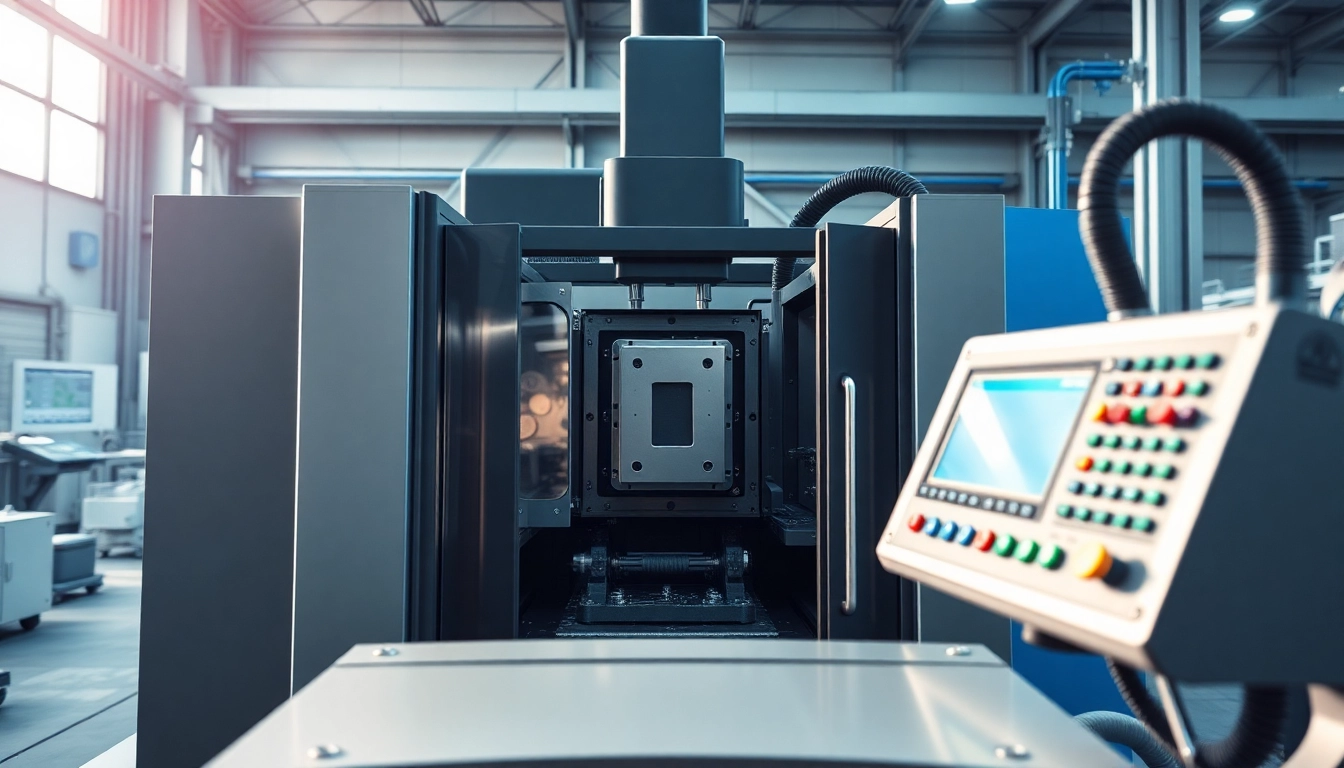

Key Components of Injection Molding Machines

Understanding the key components of injection molding machines can provide insight into their operation and efficiency:

- Injection Unit: This component is responsible for melting and injecting the resin into the mold.

- Clamping Unit: This part holds the mold in place during the injection process and must be robust enough to withstand the pressure from the melted material.

- Mold: The actual metal form that shapes the melted resin into the final product.

- Control System: Offers precision in controlling temperature, pressure, and injection speed, contributing to the overall efficiency of the process.

Types of Injection Molding Machines

Injection molding machines can be categorized into three primary types based on their technology and operational mechanisms. Each type serves distinct applications and offers varying advantages.

All-Electric Injection Molding Machines

All-electric injection molding machines utilize electric motors for all servo axes of the machine, eliminating the need for hydraulic systems. This results in several advantages, including:

- Energy Efficiency: These machines consume significantly less energy compared to their hydraulic counterparts.

- Precision: Enhanced control over the movements allows for improved accuracy in part production.

- Lower Maintenance Costs: With fewer moving parts and no hydraulic fluid, maintenance needs are minimized.

Servo-Driven Injection Molding Machines

Servo-driven machines represent a hybrid of electric and hydraulic technologies. They utilize electric servos to regulate hydraulic functions, providing several benefits:

- Speed: The responsiveness of servo systems enables faster injection and cycle times.

- Flexibility: Ideal for complex parts and varied production runs, they can adjust speeds and pressures in real-time.

- Reduced Energy Consumption: While hydraulic, the servos only draw power when actively being used, leading to energy savings.

Direct Press Injection Molding Machines

Direct press machines are characterized by their use of a direct pressure system for clamping molds. They are particularly suited for large and heavy components, offering unique advantages:

- Strong Clamping Force: Capable of handling larger molds with high pressure, making them ideal for large-scale products.

- Stability: The two-plate center clamping structure provides maximum stability during the injection process, critical for accuracy.

TEII Series: All Electric Injection Molding Machine

Features and Specifications

The TEII Series from Topstar represents cutting-edge technology in all-electric injection molding machines. Designed for optimal performance, these machines offer a variety of specifications that enhance production capabilities:

- Clamping Force: Ranging from 90 to 460 tons, making them suitable for a variety of applications.

- High-Rigidity Templates: Ensures that the product remains stable during the molding process, thus protecting the mold better.

- Modular Design: Allows adaptation to various working conditions and facilitates ease of maintenance.

- Interactive Interface: The user-friendly interface promotes ease of operation, enhancing the user experience.

Applications and Use Cases

TEII Series machines excel in diverse industrial applications, providing solutions for:

- Automotive parts production where precision is critical.

- Consumer electronics components that require complex shapes.

- Medical devices that must meet stringent regulatory standards for quality and reliability.

Comparative Advantages

The TEII Series offers various benefits when compared to competitive models:

- Energy Savings: Their electric mechanism reduces energy costs significantly when compared to hydraulic machines.

- Consistency and Quality: The precision of movement leads to less waste and higher quality products.

TMII Series: Servo-Driven Injection Molding Machine

Innovative Technology Integration

The TMII Series is engineered with a focus on providing an integrated solution to the injection molding process, linking multiple devices through a single control interface. This innovative integration is designed to optimize manufacturing workflows.

Performance Metrics

Highly known for their performance, the TMII Series machines provide impressive metrics:

- Speed: Fast cycle times ideal for high-volume production.

- Precision Control: Automatic compensation features ensure that mold opening occurs without lag, maintaining part accuracy.

User Experience and Interface

The intuitive interface of the TMII series facilitates easy operation, allowing for real-time adjustments and feedback during the production process. This not only simplifies the user experience but also contributes to operational efficiency.

TH Series: Direct Press Type Injection Molding Machine

Overview of Direct Press Technology

The TH Series focuses on leveraging direct press technology, which enhances the capabilities of clamping and injection processes. This series is ideal for producing larger components with robust specifications.

Production Capabilities

With a wide range of capabilities, TH series machines can handle:

- Large-Format Products: Perfect for parts that need extensive clamping and deep cavity molds.

- High Production Volumes: Engineered for high-output scenarios without compromising on quality.

Suitable Applications in Industry

The versatility of the TH Series aligns with various industrial demands, making them suitable for:

- Diverse automotive components, especially for heavy-duty applications.

- Large household items and industrial containers that require stability and strength.

Conclusion

Injection molding machines represent a vital aspect of modern manufacturing, enabling various industries to produce high-quality, intricate parts at scale. With advanced technology applied in Topstar’s TEII, TMII, and TH series machines, manufacturers can achieve unprecedented efficiency, precision, and versatility in their production processes. As industries continue to evolve, investing in cutting-edge injection molding technology stands as a key factor in staying competitive in the marketplace.