1. Introduction to Machine Vision

In today’s rapidly evolving industrial landscape, machine vision has emerged as a transformative technology. Integrating advanced imaging techniques with computational capabilities, machine vision enables machines to interpret visual data much like humans do. This guidance empowers industries to streamline operations, enhance quality control, and automate processes across various sectors.

1.1 What is Machine Vision?

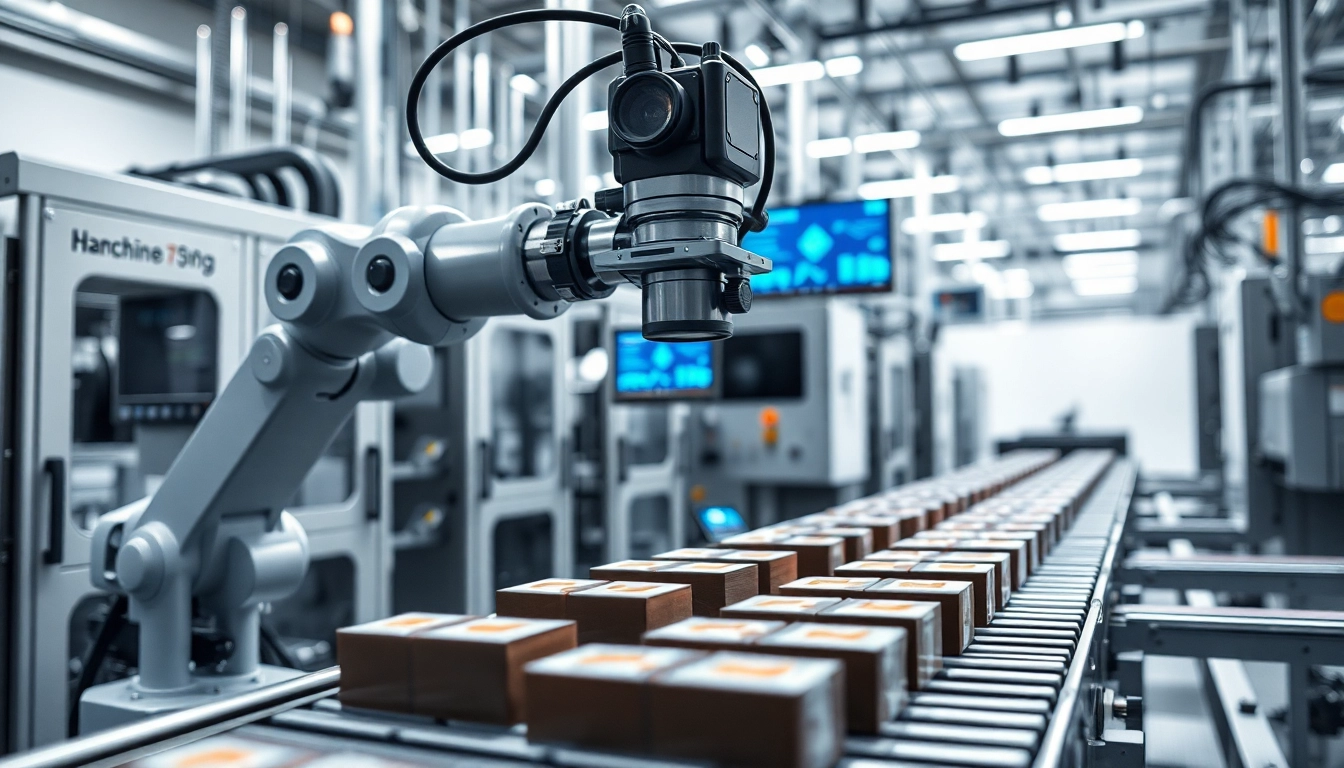

Machine vision is defined as the technology that provides imaging-based automatic inspection and analysis. This process utilizes cameras and imaging software to capture visual information, which is then processed and interpreted by computers. Essentially, machine vision allows machines to ‘see’ and make decisions based on what they see, often leading to improved accuracy and efficiency in various applications.

1.2 Importance of Machine Vision in Industry

The significance of machine vision in industries cannot be overstated. With the growing emphasis on automation, manufacturing processes have increasingly relied on machine vision systems for tasks such as quality assurance, defect detection, and sorting. This technology eliminates human error, speeds up inspection processes, and provides consistent outcomes that enhance the production quality.

1.3 Common Applications of Machine Vision

Machine vision is utilized in a variety of applications spanning across multiple sectors:

- Quality Control: Machine vision systems ensure that products meet quality standards through detailed inspections.

- Automated Guided Vehicles (AGVs): They use machine vision to navigate and identify obstacles in industrial environments.

- Barcode and QR Code Reading: An essential function in logistics and inventory management systems.

- Robotics: Machine vision plays a critical role in enabling robots to perform tasks that require precision and speed.

2. How Machine Vision Works

2.1 Core Components of Machine Vision Systems

A standardized machine vision system consists of several core components:

- Cameras: High-resolution cameras capture the visual data from the environment.

- Lighting: Proper illumination enhances image quality and ensures accurate readings.

- Image Processing Software: This software analyzes the captured images, extracts relevant features, and performs decision-making tasks.

- Output Display: Systems often have a way to communicate results back to the operators or integrated systems.

2.2 Image Processing Techniques

Image processing is at the heart of machine vision technology. It involves multiple techniques such as:

- Image Acquisition: Capturing images using cameras under different conditions.

- Image Enhancement: Improving the visual quality of the image for analysis, including noise reduction and contrast adjustment.

- Feature Extraction: Identifying specific elements within the image such as edges, shapes, and colors.

- Image Classification: Categorizing images based on the data extracted, often using machine learning algorithms.

2.3 Calibration and Accuracy in Machine Vision

Calibrating machine vision systems is crucial for ensuring accuracy and reliability. Calibration typically involves:

- Geometric Calibration: Ensuring the spatial measurements and perspectives are accurate.

- Color Calibration: Adjusting color responses to ensure consistency across different lighting conditions.

- System Validation: Regular checks to confirm that the system operates within the desired performance specifications.

3. Types of Machine Vision Systems

3.1 1D, 2D, and 3D Vision Systems

Machine vision systems can be categorized based on the dimensionality of the data they analyze:

- 1D Vision Systems: Typically used for reading barcodes or lines on a surface.

- 2D Vision Systems: Capture two-dimensional images and are widely used for quality inspections, with common applications in packaging and electronics.

- 3D Vision Systems: Utilize depth information to analyze the shape and contour of objects, invaluable in robotics and complex assembly tasks.

3.2 Fixed vs. Mobile Machine Vision Systems

Machine vision systems can also be classified based on their deployment mode:

- Fixed Systems: These are stationary systems designed to monitor a specific area or process.

- Mobile Systems: These systems are flexible and can be repositioned, often used in robotics and automated vehicles for navigation and object detection.

3.3 Thermal and Spectral Imaging in Machine Vision

Beyond traditional imaging techniques, machine vision also encompasses thermal and spectral imaging:

- Thermal Imaging: Captures heat emitted from objects, often used in critical applications like fire detection, security, and predictive maintenance.

- Spectral Imaging: An advanced technique capturing a wider spectrum of light beyond visible wavelengths, useful in quality control of materials and food safety assessments.

4. Benefits of Implementing Machine Vision

4.1 Increased Efficiency and Productivity

By automating the visual inspection processes, machine vision systems can significantly enhance efficiency and productivity. Machines can operate continuously, leading to reduced downtime and faster throughput compared to manual inspection.

4.2 Cost Reduction and Waste Minimization

Effective implementation of machine vision can lead to substantial cost savings. By catching defects early in the production process, companies can minimize material waste, reduce rework costs, and optimize their supply chain efficiently.

4.3 Enhanced Quality Control and Consistency

Machine vision systems provide consistent inspection criteria, eliminating variability introduced by human inspectors. Enhanced quality control leads to increased customer satisfaction and can strengthen brand reputation.

5. Future Trends in Machine Vision Technology

5.1 Integration with Artificial Intelligence

The combination of machine vision with artificial intelligence (AI) is set to revolutionize the industry. AI algorithms can interpret data more efficiently, enabling systems to learn from past inspections and adapt to new conditions, thus improving accuracy over time.

5.2 Advancements in Camera Technology

Camera technology continues to evolve, driving improvements in image resolution, processing speeds, and sensory adaptations. Innovations such as 4D imaging and hyperspectral sensors will further enhance machine visual capabilities.

5.3 The Role of Machine Vision in Industry 4.0

As part of the broader Industry 4.0 movement, machine vision systems will play a pivotal role in the smart factories of the future by enabling interconnected systems to communicate and make decisions autonomously. This shift will lead to more adaptive manufacturing processes, personalized production, and real-time data analysis, solidifying the importance of machine vision in modern industrial applications.